About

KTPL, widely recognized for our premium quality water filter media in the worldwide. Our products are designed & developed with consultation with scientist, Ministry of Science and Technology, Department of Scientific and Industrial Research. Our technical capability through our quality products as we are keen to associate with your esteemed organization.

Adroit team of professionals & Well-equipped factory setup plays an important role in the growth of our company. We offer these products at reasonable rates and deliver these within the promised time-frame.

Owing to the experienced group of employees and latest technology, we are able to produce very high quality products and services. Our product undergoes various quality testing procedures at each and every level of production to ensure flawless delivery of product and services. Our products are made from very superior quality of raw material and upgraded machinery to ensure their high quality for increased durability. We are committed to provide superior quality and this commitment is not broken at any cost.

Within a limited period of time, we have been able to carve a niche for ourselves by fulfilling the exact requirements of the customers consistently. We take several measures to ensure that customers have a delightful experience of conducting business with us.

Our Exemplary Success Factors:

- Wide range of products with a vast application area

- Unsurpassed quality standards

- Maintenance of high ethical standards

- Focus on long term, mutually beneficial relationships with the customers

Mission & Vision

Committed To Offer Best Quality Products At Affordable Cost And To Provide Solution The Redefining The Science Of Water Treatment.

Our Aim To Become The Best Quality Conscious Organizations In Implementing Water Treatment Solutions In The World.

Manufacturing Areas

We have a world class infrastructure area about 75000 sq ft that is equipped with modern equipment and multiple amenities that enable a healthy work environment for the employees. Our production and other processes are carried out in a standardized manner to maintain consistency in the quality we offer. In order to achieve maximum operational efficiency, we have segregated our facilities in to multiple departments on the basis of the functions performed by them. These departments include production, quality assurance, service, administration and logistics.

Team & Professionals

We have a skilled team of self-motivated professionals which is driven to achieve the organizational objectives in the most efficient manner possible. These individuals are proficient in their respective areas of expertise and are focused on giving their best to the organization. Hired considering their experience, knowledge levels and attitude, these professionals are provided a conducive work environment that enables their personal growth along with professional advancement. We encourage them to stay abreast of the latest market happenings so as to devise applicable solutions for the customers.-

Business Overview

Infrastructure: State-of-the-art equipment and stringent quality controls at each step aid KTPL to focus on all our formulations. We ensure that our machines see timely upgrades towards the maintenance of product quality. We utilize the best available technology to be reliable, economically and environmentally efficient, and adherent to globally accepted safeguards and standards.

Client Satisfaction: We are consistently serving our customers for more than four decades. Due to our exceptional product quality and customer service, we have gained high credibility and extensive customer approach over years of experience. Our client feedback system has helped us to understand the needs of our clientele.

Packaging: We provide our customers best packaging services to ensure the preservation of quality in all our products. All our packagings are world-class - appealing as well as sturdy at the same time.

Warehouses: We have well-built and large warehouses, well suited to the storage needs of our specialised formulations. They are clean and hygienic; apart from being meticulously organised. Our team ensures timely service with minimal chances of errors.

Products

-

Manganese Dioxide

Manganese DioxideManganese Dioxide KT is water filter media used for reducing iron, manganese and hydrogen sulfide from drinking water. Manganese Dioxide KT oxidises and precipitates soluble iron and manganese and the precipitates are filtered out in the granular bed and removed by backwashing. PHYSICAL PROPERTIES • Color: Dark brown• Bulk Density: 45-50 lbs./cu. ft. • Specific Gravity: 2.0 gm/cc• Effective Size: 0.43 mm• Uniformity Coefficient: 2.0 CONDITIONS FOR OPERATION Water pH range: 6.2-8.5 Maximum water temp: 100°F/38°C Bed depth: 24-36 in. Freeboard: 50% of bed depth (min.) Service flow rate: 2-5 gpm/sq. ft. Backwash flow rate: At 60°F 8-10 gpm/sq. ft. Backwash expansion rate: 20-40% of bed depth (min.) MAXIMUM LIMIT Iron 15 ppm Manganese 5 ppm Hydrogen Sulphide 2 ppm

-

AC-KT ( Activated Carbon)

AC-KT ( Activated Carbon)KTPL AC-KT coal based activated carbon is manufactured from selected bituminous coal and is designed for reduction of tastes, odours, dissolve organics from raw water. Activation is carefully controlled to produce exceptionally high internal surface area with optimum pore size for the adsorption of a broad range of high and low molecular weight organic contaminants. To obtain maximum efficiency of the activated carbon in the adsorption process, it is desirable to have the greatest possible surface area in the smallest practical volume and AC-KT has a great surface area of 877 square meters per gram. his results in high efficiency and greater system economy. AC-KT requires periodic backwashing to eliminate accumulated suspended matter and to re-grade the filter bed. AC-KT has replaced when the filter bed loses the capacity for reduction of taste and odor. PHYSICAL PROPERTIES: Color: Black Bulk Density: 30 lbs./cu. ft. Effective Size: 0.45-0.55 mm Ash Content: Max 2.5% Iodine Number: 900 mg/g Moisture as packed: Max 5% pH 10 CONDITIONS FOR OPERATION: Bed depth: 30-35 inch. Freeboard: 50% of bed depth (min.) Empty bed contact time 4 minutes minimum Dissolved Oxygen Concentration 4 ppm (mg/L) Service flow rate: 5 gpm/sq. ft. Backwash flow rate: 9-12 gpm/sq. ft. Backwash bed expansion: 30-40% of bed depth

-

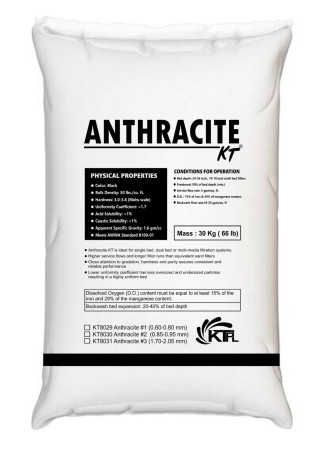

Anthracite KT

Anthracite KTAnthracite is an excellent filter media for water clarification in drinking or industrial use, when used in combination with filtering sands. It is one of the most used filtering media. It is a good complement for the mixed filters, in company of sand or green manganese sand. Due to the special shape of its grains, it allows the suspended particles to be retained in the depth of the filtering bed. Compared to a sand filter, this filtering medium allows a higher flow, less pressure drop and a better and faster backwash. PHYSICAL PROPERTIES: Color: Black Bulk Density: 50 lbs./cu. ft Hardness: 3.0-3.8 (Mohs scale) Uniformity Coefficient: <1.7 Acid Solubility: <1% Caustic Solubility ((1% NaOH @ 190°F)) : <1% Apparent Specific Gravity: 1.6 gm/cc Meets AWWA Standard B100-01 Mesh Size : 0.6 x 0.8 mm , 0.85 x 0.95 mm, 1.70 x 2.05 mm CONDITIONS FOR OPERATION: Bed depth: 24-36 inches Freeboard: 50% of bed depth (min.) Service flow rate: 5 gpm/sq. ft. Dissolved Oxygen (D.O.) content must be equal to at least 15% of the iron and 29% of the manganese content. Backwash flow rate: 18-25 gpm/sq. ft ADVANTAGES The shape of particles allows suspended particles to be retained over the depth of the filter bed It complements mixed filters very well, particularly Green and Manganese Sand filter media Allows for higher flow rate compared to sand Smaller pressure drop compared to sand Faster backwash rate compared to sand High resistance to a variety of chemicals Greater physical strength for use in industrial water purification. Prevents filtration blockage and more. Prevention of mad ball forming at the surface of the sand layer. Can easily transform from Single Media Filtration to Dual Media Filtration (sand).

-

KT-225 ( Ion Exchange Resin )

KT-225 ( Ion Exchange Resin )KT-225 Ion exchange resin is synthetic polymeric beads or granules that contain charged sites that can attract, from a solution, ions of the opposite charge, in order to remove or concentrate impurities used for water softening application. It is a high capacity strongly acidic cation exchanger in bead form. Physical Properties Color : Yellow Ionic Form : Sodium Exchange Capacity (mEq/ml) : 2.0 Moisture % : 42-50 Reversible Swelling % Na to H : 7% Shipping Density ( g/l) : 820 Particle Size Distribution (mm) : 0.45-1.0 Salt Consumption (g/l) : 150 Hardness Level (mg/L) : 1000 Condition for Operation Operating Temperature ( Max) : 120OC Bed Depth : 800 mm Service Flow Rate : 40 m/h Regenerant : Nacl Nacl Concentration : 5-10%

-

Greensand KT

Greensand KTGreensand KT is effective at higher operating temperatures and higher differential pressures than ordinary manganese greensand. Greensand KT is a black filter media used for removing soluble iron, manganese, hydrogen sulfide, arsenic, and radium from water supplies. The manganese dioxide coated surface of Greensand KT acts as a catalyst in the oxidation reduction reaction of iron and manganese. Systems may be designed using either vertical or horizontal pressure filters, as well as open gravity filters. Greensand KT is a proven technology for iron, manganese, arsenic, radium, and hydrogen sulfide removal. Unlike in-situ treated media, there is no need for extensive preconditioning of filter media or lengthy startup periods, during which required water quality may not be met. PHYSICAL PROPERTIES Physical Form : Black Granules Apparent Density : 77 lb/cu.ft Specific Gravity. : 2.4 approx Porosity : 0.45 approx Screen Grading : 20 x 60 mesh Effective Size. : 0.30 to 0.35 mm Uniformity Coefficient : < 1.60 pH Range : 6.2 to 8.5 Backwash Rate : 12 gpm/sq.ft. @ 55ºF Service Flow Rate : 2-12 gpm/sq.ft Minimum Bed Depth. : 15 inches OPERATING CONDITIONS Bed Type : Greensand KT 15 inches Backwash : Sufficient rate using treated water to produce 45% bed expansion Air/Water Scour. : Optional using 0.7 to 2.5 cfm/sq.ft. with a simultaneous treated water backwash at 5.0 to 5.5 gpm/sq.ft. Raw Water Rinse. : At normal service flow rate for 5 to 10 minutes or until effluent is acceptable FEATURES Removal of iron, manganese, and hydrogen sulfide Effective over wide PH range High tolerance of oxidizers such as chlorine Low attrition for long bed life

-

CC-KT (Coconut Shell Activated Carbon)

CC-KT (Coconut Shell Activated Carbon)CC-KT Coconut shell granular activated carbon is specifically designed for the reduction of chloramines and hydrogen sulfide from potable water. Activation is carefully controlled to produce exceptionally high internal surface area with optimum pore size for the adsorption of a broad range of low molecular weight organic contaminants and oxidizing agents like chlorine and ozone.PHYSICAL PROPERTIES: Color: Black Bulk Density: 30 lbs./cu. ft. Effective Size: 0.55-0.75 mm Ash Content: 1.5% Iodine Number: 1,000 mg/g Moisture as packed: 2% pH 10 CONDITIONS FOR OPERATION: Bed depth: 26-30 inch. Freeboard: 50% of bed depth (min.) Service flow rate: 5 gpm/sq. ft. Backwash flow rate: 10-12 gpm/sq. ft. Backwash bed expansion: 30-40% of bed depth

-

KTM ( 85% purity MnO2 )

KTM ( 85% purity MnO2 )KTM is Grade Manganese Dioxide water filter media used for reducing iron, manganese and hydrogen sulfide from drinking water. KTM oxidises and precipitates soluble iron and manganese and the precipitates are filtered out in the granular bed and removed by backwashing. PHYSICAL PROPERTIES • Color : Black• Bulk Density : 125 lbs./cu. ft. • Specific Gravity : 3.8 gm/cc• Effective Size : 0.46 mm• Uniformity Coefficient : 2.4 CONDITIONS FOR OPERATION Water pH range : 6.2-8.5 Maximum water temp : 100°F/38°C Bed depth : 12 inch. Freeboard : 35% of bed depth (min.) Service flow rate : 4 gpm/sq. ft. Backwash flow rate : At 60°F 25-30 gpm/sq. ft. Backwash expansion rate : 20-40% of bed depth (min.)

-

KT-20 (Iron Removal Media)

KT-20 (Iron Removal Media)KT-20 Iron removal filter media acts as an insoluble catalyst to enhance the reaction between dissolved oxygen (D.O.) and the iron compounds and remove dissolved iron and manganese compounds from raw water. It removes iron upto 20 PPM, manganese upto 15 mg /L and other heavy metals arsenic, Hydrogen Sulfide, Uranium, Radium, Radionuclide.PHYSICAL PROPERTIES: Color: Black Bulk Density: 35-40 lbs./cu. ft. Mesh Size: 12 x 50 Specific Gravity: 2.0 gm/cc Effective Size: 0.48 mm Uniformity Coefficient: 2.7 CONDITIONS FOR OPERATION: water temp: 100°F/38°C Water pH: 6.8-9.0 Dissolved Oxygen : 15% of iron & 29% of manganese content. Bed depth: 30-36 in. Freeboard: 40% Backwash rate: 10-12 gpm/sq. ft. Service flow rate: 3.5-5 gpm/sq. ft

-

KT-TS ( Coated Treated Sand )

KT-TS ( Coated Treated Sand )High Grade MnO₂ Powder is imprignated to increase surface area for better filtration. KT-TS acts as a catalyst in the oxidation reduction reaction of iron and manganese.PHYSICAL PROPERTIES: Color: Black Bulk Density: 1450 Kg/m3 Specific Gravity : 3.9 gm/cc Effective Size: 0.45-0.8 mm Uniformity Coefficient : 2.6 Moisture as packed: Max 3% pH Range : 6.8-8.9 CONDITIONS FOR OPERATION: Water Temp: 100OF/ 38OC Water PH : 6.5-9.0 Bed Depth : 35-45 Inch Freeboard : 42% Backwash Rate : 10-15 gpm /sq.ft Service Flow Rate : 3.4-5.2 gpm/sq.ft Backwash Expansion Rate : 25-30 % of Bed Depth ( Min)